Hot selling manual hand pressused red fly ash clay brick making machine

Product Description

This machine used to make the clay hollow blocks with size of 240*115*75mm; 250*115*100mm; 300*150*100mm;the block size can be changed by updating the related molds,material can be as clay ,soil,or even concrete.This manula press brick making machine can meet the brick requirement of small construction engineering, is the best selection of small scale brick factory or mobile brick factory. The finished bricks is widely used in buildings, road paving, squares, gardens, landscaping, city constructions etc. It is populared in tanzania,kenya,ghana,ethiopia etc.

| LYA-B2 Specification of Manual Interlock brick machine |

| Machine Type | LYA-B1 Manual Clay Brick Machine |

| Dimension | 600*450*1000mm |

| Forming cycle | 15-30 Seconds |

| Brick size | Customized available |

| Material | Cement;Clay/Mud/Earth;Fly ash |

| Power | Manual operation |

| Operating staff required | 1~2 staff |

| Total weight | 200-230kg |

| Capacity | 1Pcs each Pressing |

| Color | Customized |

| Production(Pcs/h) | 100~110 |

| Warranty | 1 Year |

Working Process:

Put enough raw material into the feeding box by spade or just hand,then the move open the pressing head,move the

box above the mould box ,let the raw material drip in the mould box,when it is almost full,just shave the material box to make the mould box load fully.Then close the pressing head,you need press the material inside by manpower,after finished ,you can take the blocks out on the shelf for drying.

One set mould included with the machine,engineers will give one fully operational instruction for reference.Before shipping,we will do trial producing for you, and the video will be sent for confirmation.we also have the diesel engine model,can do customization for customers.

Advantages

1) Easy Operation. This machine can be operated by any workers just by short-time learning.

2) High-efficiency. With low consumption of material,every brick can be made in 30- 40s,which will ensure a quick production and good quality.

3) Flexibility. QMR2-40 is with a small body size,so it can cover less land area.Moreover, it can be moved from one to another place easily.

4) Environment-friendly. This brick machine works without any fuels just under operation of human.

5) Worth for your investment. Compared with other bigger machines,QMR2-40 can take little cost and return you a good output.

6) Adjustable.Can produce different height of briks across adjusting the bolt under the mould.

7)Made under strict quallity control. Each of our machine needs to be tested as a qualified product before leaving factory.

Company Information

We are Zhengzhou LYA machinery company, from China, and we are the supplier and manufacturer ,specialize in block/brick machinery many years .We have rich experience and high service quality including pre-sale,in-sale and after-sale service.

Our main products are brick making machine ,concrete block production line and plastic interlock block mold etc.Quality is the core of our company. Advanced inspection equipment and stringent quality control tests make us pass ISO9001:2008 certification.

We implement "Three-Guarantee" installation and debugging for free, focusing on quality and after-sales services. Our company also supplies training services to clients.

Our products have been exported to Africa, South America, Middle East,South Asia,East Europe,Russia and so on.

Best price with high quality.

FAQ

1.Q: Can I trust your company and your block machine?

A: Yes. Our customers come from all over the world,We have rich experience in export inspect. If you have concerns,we can take credit protection.

2.Q: What types block your machines can make?

A: Various block/brick including interlocking brick,hollow brick, solid block, interlocking paving block,curb stone.

3.Q: How long is the warranty of your machine? Do you supply spare parts?

A: Our warranty period is one year generally. The spare parts tools is necessary.Of course we supply them.

4.Q: How to make different size and shape brick by one machine?

A: Usually one machine can make different brick,just need to replace different mould then can make different brick.

5.Q: Do you provide after-sale service?

A: Yes. We have one professional after-sale service team could solve your problems promptly and thoroughly ,we have our own office in kenya.

6.Q: Do you have a good price ?

A: We are factory,we would like to offer one competitive price for you.Any inquiry welcome here and glad to offer updated price for you with patience.

7.Q: How long for delivery time after payment ?

A: Normally 15-20 days after your deposit.

8.Q:Raw material ratio:

A:Method one: 5% cement + clay:

Method two: 8% cement + clay;

Method three: 10% cement + clay;

Method four: 10%cement + sand + water.

9.Q:How about the working life of our machine?

A:Our machine can be used for over 8 years.

Certifications

Packing & Delivery

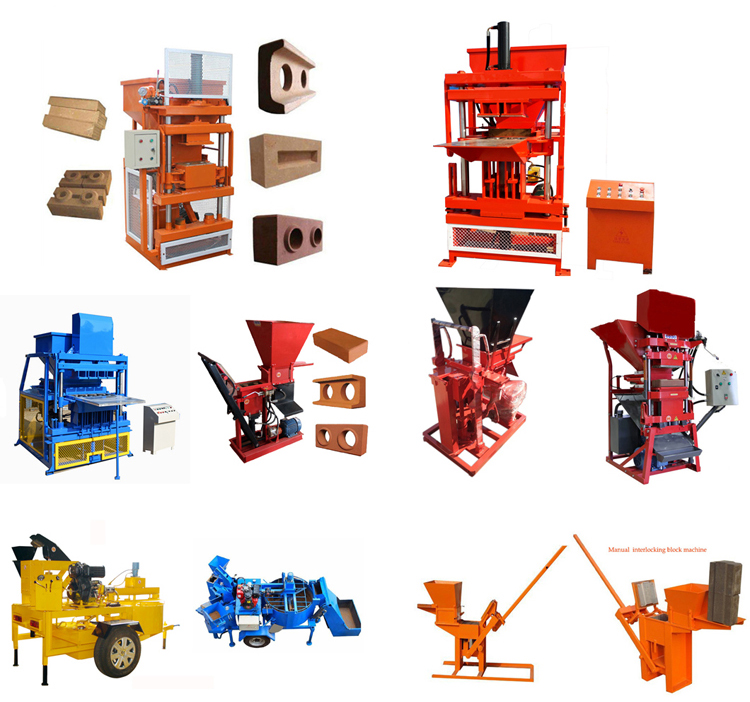

Related Product

Contact Us